Hydraulic Container Flipping Machine

-

Introduction:

This hydraulic container flipping machine provides an ideal container overturning platform to tilt, rotate, or invert cargo containers. This machine can be designed with 1 container system or 2 containers system. The container flipping machine can be used used in industries like manufacturing, agriculture, waste management, food processing, and metal recycling. The main components of the system:

-

Anti-drop System

-

Weighing System

-

Anti-Bulging System

-

Hydraulic Door Opening and Closing System

-

Anti-fall System:

-

This system is applied to the fully hydraulic container flipper/tipper.

-

In the original container tipping process, the absence of an anti-drop system meant that, in cases of human error or other extreme conditions, the container locks could fail to secure properly. This could lead to the container detaching from the equipment, resulting in serious safety incidents during production.

-

To address these shortcomings, our company has added an anti-drop system on this basis. The system consists of two completely independent anti-drop mechanisms:

-

System 1: A lock control system that uses proximity sensors as the signal source.

-

System 2: A lifting control system that uses proximity switches as the signal source.

-

System 1 Principle:

This system controls the operation of the twist locks. Each of the four lock bases on the main moving frame is equipped with a proximity sensor. By default, the sensors are in the “off” state and control the solenoid valves in the lock’s hydraulic circuit. The solenoid valves are also normally in the “off” state, preventing the twist locks from rotating.

During operation, when all four sensors detect the container’s top cover within 3 mm, the sensors switch to the “on” state, the solenoid valves open, and the twist locks are allowed to rotate for locking. In addition, a bidirectional hydraulic lock is connected in series in the twist lock hydraulic circuit to prevent accidental unlocking in the event of a hydraulic system failure.

System 2 Principle:

If any one of the twist locks is not fully locked (or not fully released), the lifting hydraulic cylinder will remain inactive.

-

Weighing System:

-

This weighing system performs real-time measurement of materials during the process of container filling. It helps reduce loading time, lowers the need for additional equipment, eases labor intensity, and improves production efficiency. The weighing accuracy complies with or exceeds the national standard for Grade 3 scales (≤ 0.3%). The target weight can be set freely, and the system includes a preset weight alert and a full-weight alarm function.

-

Example of Use:

When the weight during filling on the tipping platform reaches a preset value before the target weight, the system triggers an audible and visual alarm. Once the target weight is reached, the system issues a “full weight” signal and outputs a switching signal (relay output) to lock the user’s filling system, such as by stopping the motor or conveyor belt. This eliminates the need for the operator to continuously monitor the filling weight during material loading.

-

Anti-Bulging System:

-

In recent years, due to the high fluidity of materials such as cement and fly ash, problems such as container bulging and cracking have become increasingly common. To address this issue, our company developed the “Container Tipper Anti-Bulging System” in 2017.

-

This system is an auxiliary component of the container tipper. Driven by the tipper’s hydraulic pump, it provides effective protection for three sides of the container (or two sides for the dual-tilt type system). The system significantly reduces container deformation and cracking, and provides substantial cushioning against the impact of bulk materials.

-

Operating Principle:

After the container tipper locks the container in place, the operator uses the anti-bulging control lever (or remote control joystick) to lower the anti-bulging baffles—three baffles for the single-tilt type and four for the dual-tilt type. Once all baffles have fully lowered to their lowest position, the loading operation can begin. After loading is complete, the baffles are retracted, allowing the vehicle to depart.

-

Hydraulic Door Opening and Closing System:

Before operating the container door closing system, ensure that the container is detached from the vehicle and that there are no obstructions within the door opening range. Door opening procedures:

First, ensure the door closing arm is fully retracted.

Manually unlock the container door latch, freeing the door. Install a door lock on the lower corner fitting of the container (this step is crucial; it serves as a safety measure to prevent the container door from suddenly opening fully and falling due to misoperation).

1. Operate the door closing arm so that the catch on the arm extends behind the door locking rod.

2. Operate the door closing arm to open the container door (if there are two sets of door closing arms, open the right/outer door first).

3. The door closing procedure is the reverse of the opening procedure.

This door closing system can be operated at any container angle between 0 and 90 degrees.

Operating the door closing arm after the container door is open is strictly prohibited, as this may result in the container door opening fully. For other precautions, refer to the tilting machine manual.

-

Type:

-

Single Truck-Lane 90° Flipping System:

-

Single Truck-Lane 180° Flipping System:

-

Double Truck-Lane 90° Flipping System:

-

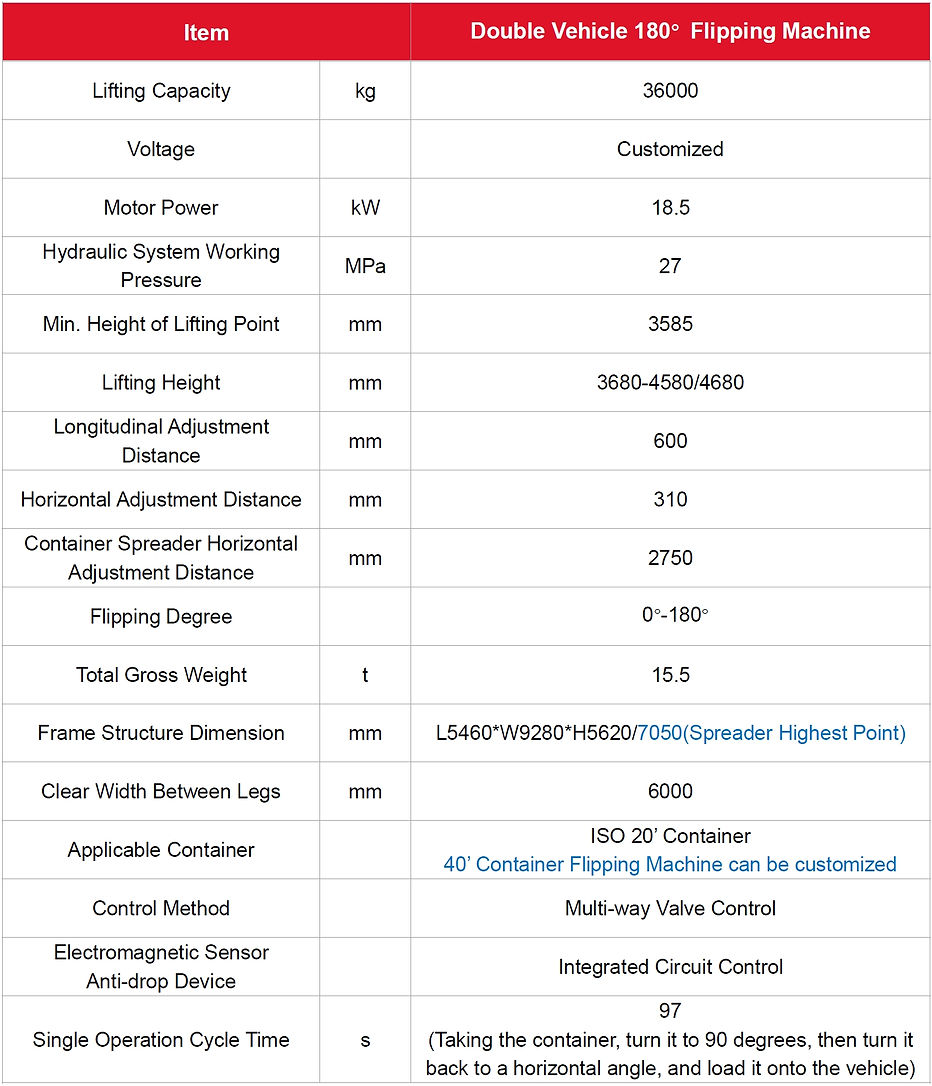

Double Truck-Lane 180° Flipping System:

-

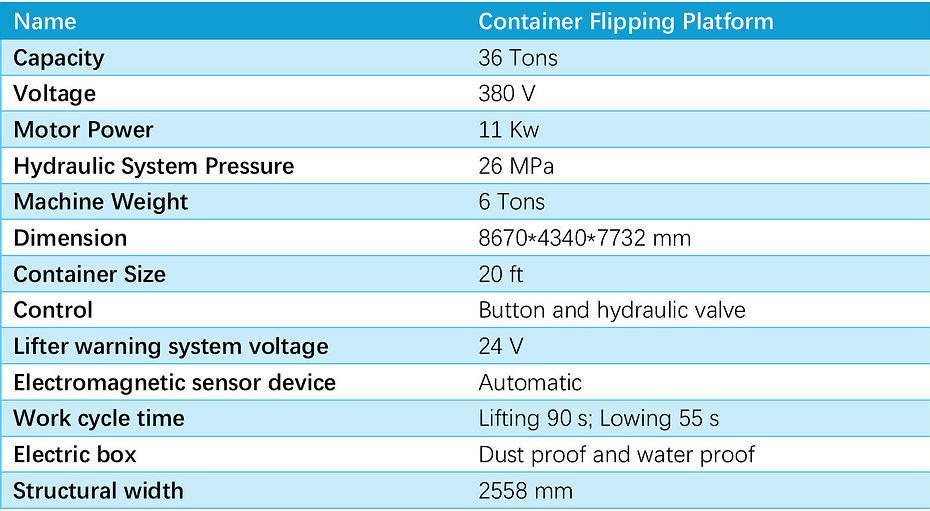

Container Flipping Platform:

-

Sunken platform: